Lighter And Stronger

Thanks to the lamination technology, where the power of design is combined with engineering, the point problems of natural stone are eliminated, and it is also possible to realize the designs of your dreams.

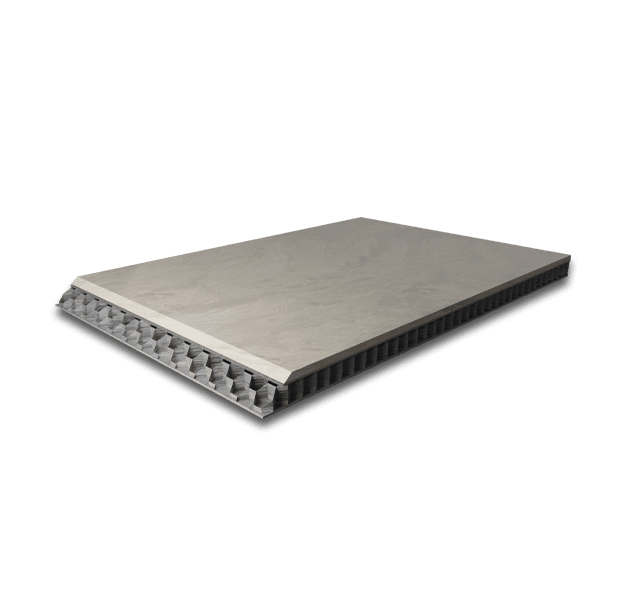

In addition to minimizing the size by ensuring that the weight caused by the density of the marble is produced in thinner thicknesses (4-8 mm), the system reduces the sensitivity of the marble, which has a fragile structure, to 70% in products produced by laminating with materials such as aluminum honeycomb (honeycomb). It provides up to 35% lightness and up to 35% increase in strength.

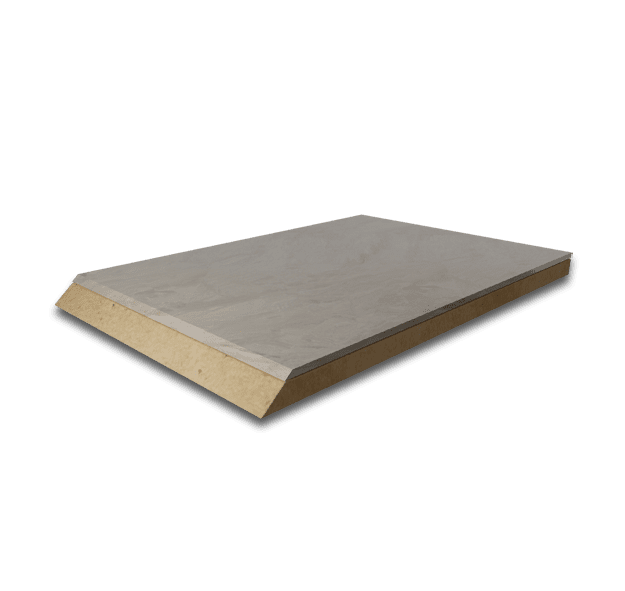

While producing alternative solutions for applications that require lamination technique, lightness and strength at the same time; It is laminated with natural stone between 4-8 mm with different support materials such as honeycomb, MDF and ceramic according to the areas where the product will be used in the end, making areas where natural stone has not been able to enter until now.

Note: You can consult our technical team for the materials and natural stone thicknesses to be used for your projects.

Honeycomb

MDF

SUPPORT MATERIAL

SUPPORT MATERIAL THICKNESS

RECOMMENDED STONE THICKNESS

HONEYCOMB

10-15-20 mm

4-8 mm

MDF

8-12-18 mm

Variable according to application

CERAMIC

9 mm

Variable according to application

ALUMINUM

1-2-3 mm

Variable according to application

You can contact our technical team to determine the most accurate thickness according to the detail of your projects

Lamination

Natural stones are very popular materials used in many areas such as interiors and exteriors. However, in some cases, it may not be possible to use natural stones due to their weight or factors such as defects, cracks and slopes on the surface. In such cases, natural stones are strengthened and made more durable by using lamination techniques. The laminated marble technique means that the natural stone can be produced in thinner thicknesses to reduce its weight and can be decorated in the relevant areas with the necessary lamination applications. In addition, feeding processes are applied with aluminum honeycomb material or mdf laminate coating methods in order to gain the necessary strength and sensitivity to the stone thinned to 4-8 mm. This material, also called honeycomb, provides 70% lightness and 35% resistance. However, depending on the areas where natural stones will be used, some support materials such as MDF or ceramic can also be preferred.

How is Lamination Technique Applied?

MDF or honeycomb marble lamination techniques are meticulously applied by professional teams in areas that are not prone to the use of natural stone. The lamination process starts with cleaning the natural stone surface. The cleaning process is important for the surface to adhere well to the lamination material. Then, the lamination material is applied to the stone surface. This must be done very carefully, as the material must be placed evenly on the natural stone surface and spread evenly. In addition, the material to be bonded to the surface must be precisely sized, taking into account the conditions in the area of operation. After the process is completed, the material is allowed to dry completely on the natural stone surface. Sirmersan achieves very successful results in honeycomb and mdf laminate coating processes thanks to its professional staff structure.

Advantages of Lamination Application

Developed for areas of activity where it is not possible to use natural stone, the laminated stone technique brings many advantages as well as paving the way for decorative stone preference in all spaces. These processes create a layer of protection on the stone surface, providing a durable and long-lasting usage experience. In honeycomb or mdf laminated processes, various defects or gaps on the surface are also eliminated as a result of the combination of material and stone. This can increase durability and emphasize the aesthetic appearance. Honeycomb and mdf laminated coating processes provide mechanical strength and absorb various impact and impact stresses. Moreover, by creating a natural insulation floor in the area where it is applied, it prevents negativities such as heat and sound problems. In addition, lamination techniques that lighten stone and marble can make it easier for users to make decoration changes in the space.

Price Ranges of Lamination Applications

MDF and honeycomb panel prices can be in different price ranges depending on the lamination techniques applied to natural stones, the type, size and application area of the stone. Process costs vary depending on factors such as the quality of the company that will perform the application, labor level and material costs. For example, MDF laminated prices may be more reasonable than other lamination processes due to the material used. In addition, honeycomb type techniques, which are usually applied in a factory environment, provide many advantages by making the existing natural stone durable, long-lasting and safer. Aluminum honeycomb panel price ranges may vary according to the required processing volume, surface area or operating environment. Sirmersan creates highly functional and decorative environments with alternatives that can appeal to every budget.