Since the textures, colors, and variations of natural materials continue throughout the entire material, the edges are visible in your projects and applications. At the finishing points where edges are exposed, you can utilize any of the Sirmersan Edge Works options or combine several different processes to achieve the desired aesthetics and functionality for edge and corner details of natural materials, offering limitless variety. For information on applicable areas and further details, please contact our technical team.

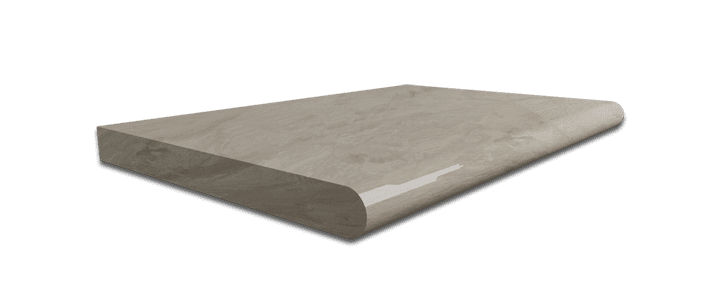

Bullnose

Two Side Bevel

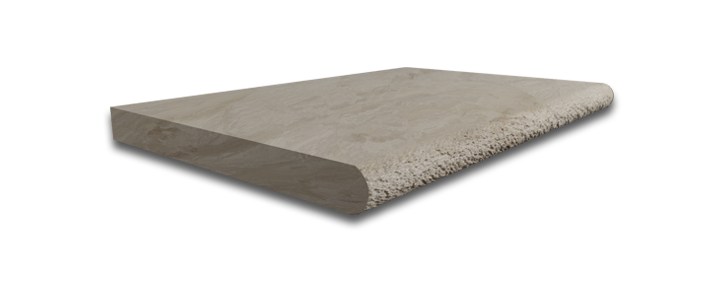

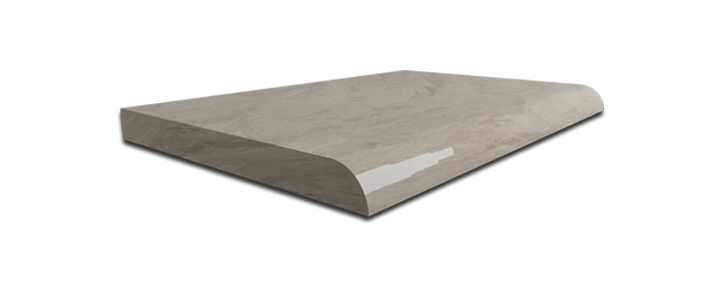

Bullnose Mucarta

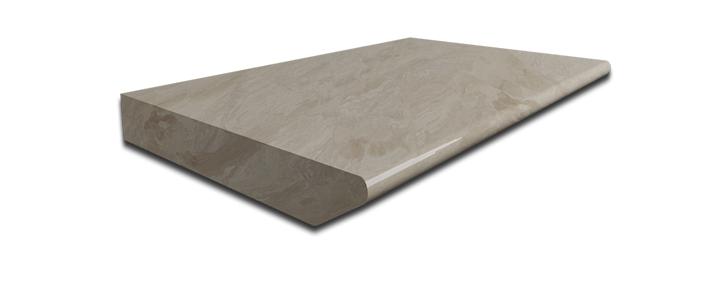

Dropper

Quarter Bullnose

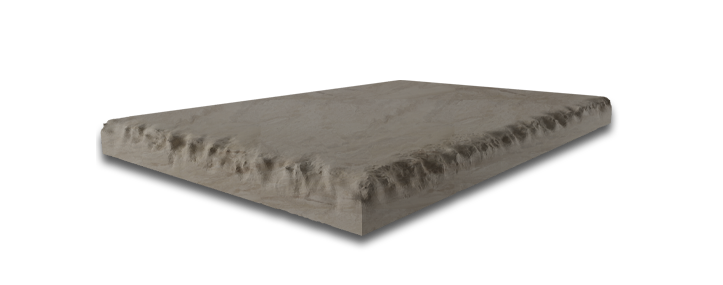

Edge Break

Sharknose

Half Bullnose

Edge Works

Various edge treatments can be applied to natural stones and marbles preferred for the relevant spaces. Marble edging, which creates some styles for details, plays an important role in completing the ambiance of the areas worked on. The edge treatments applied to marble and natural stones vary depending on the intended use of the product and the preferred aesthetic appearance. These processes provide an aesthetic appearance by smoothing or shaping the sharp or irregular edges of the stone. These processes, which are carried out by professional teams, have alternatives in different ways. According to demand, marble cutting processes can be applied to all corners or to a single corner. These applications can generally be used in decoration activities such as countertops, stair steps, wall coverings, floor coverings. Marble edge processing must be done carefully to preserve the natural structure of the stone. For this reason, edge treatments applied to marble and natural stones are done using specialized machines and tools that require high precision and experience. During the process, the temperature of the stone is kept under control and the necessary techniques are applied without damaging the structure of the stone.

What Types of Cuts are Made in Edge Processing?

Collection products preferred by users can be given many different edge shapes. There are options in various lines and shapes to be applied depending on the request or the style of the space. These processes, which are carried out with the help of company guidance according to the structure of the field of activity, help to create stylish, elegant and flashy environments with a convenient, ergonomic, safe, functional usage experience. Depending on customer demands, Sirmersan can apply many alternative edge structures such as flat, oval, serrated, glossy, tumbled, asymmetric in cutting processes.

Areas where Edge Works are Applied

Natural stone and marble edging techniques can be applied to many areas of activity. It can play an important role in completing stylish and marginal ambiances by highlighting various edge details. For example, it is quite common to use marble or natural stone on kitchen countertops, bathroom countertops, bar counters, etc. However, in these areas, sharp edges can be harsh and uncomfortable. The edge cutting process softens the sharp edges of the stone, creating a more comfortable surface for users, while also bringing an aesthetic appearance. In addition to this, many technical applications such as angular, serrated or oval marble cutting can be preferred for edge treatments in stair areas, which are frequently used in homes and workplaces. On the other hand, various edge customization designs can be made for natural stone or marble coatings applied to the floor areas that are frequently touched in homes, offices, hotels, etc. This method, which reveals the aesthetics of minimal details, reduces the risk of slipping on the floors in the activity areas, allowing safer environments to be created. In addition, marble and natural stone coatings applied to the walls can also see the same processes and offer extremely stylish visuals.

Edge Works Offered by Sirmersan to Users

Sirmersan, which applies highly customized marble and natural stone decors to various areas of use with its professional design team and expert production staff, also draws attention with its many edge shaping processes. Bullnose marble cutting technique is among the prominent methods for users who prefer oval, simple or bright styles. This technique also brings some additional options. For example, quarter bullnose marble cutting can be used as alternative styles with its partial oval appearance. Sirmersan has adopted the principle of continuing design and design works by considering all kinds of details. However, half bullnose marble cutting method is also among the techniques offered to customers who prefer oval lines. In addition, such edge cutting methods can have bold and sharp lines in terms of their shapes. One of them, the sharknose marble cut option, offers a style that highlights the entire design with its striking structure. On the other hand, some edge treatments designed for users who adopt clear and straight lines are also among the services offered by the company. Dropper marble cutting stands out as a suitable alternative. For users who prefer asymmetrical or serrated edge styles, bullnose sand blasting and edging options can create very complementary visuals. At the same time, Sirmersan’s double-sided chamfer marble cutting method, which is among the edge processes, can strengthen the ambience of the space with its charismatic and integrative style.